vibro PURIFIER

SCOPE OF PURIFIER

It is designed to enrich and classify semolina in flour and semolina mills. The machine is applied in the purification and grading of semolina and fine semolina in common wheat, durum wheat and maize mills.

APPLICATION OF PURIFIER

| At food industry |

| Flour mills |

| Semolina mills |

|

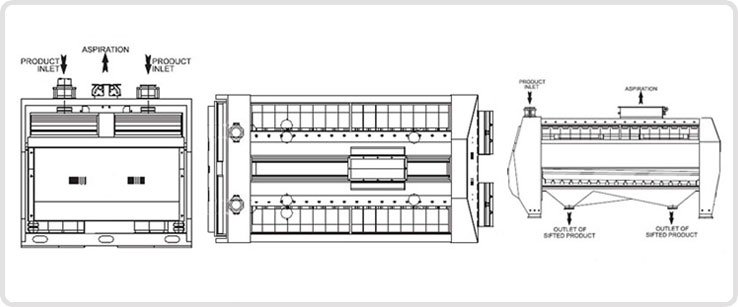

STRUCTURE OF PURIFIER

The purifier comprises three main parts :

| 1. |

A fixed main chassis |

| 2. |

An oscillating body which accommodates the sifting sieves |

| 3. |

An aspiration channel |

|

The exhaust chamber comprises two aerodynamically designed channels with a set of specially designed valves fitted above the sieves for the optimum adjustment of airflow passing through the sieves. The two channels converge at the exhaust intake, which is fitted with an adjustable butterfly valve.

WORKING PRINCIPLE OF PURIFIER

The flow rate of product is adjusted by means of a gate, which provides a perfect distribution of product along all entire width of sieves. The optimum vacuum influence is obtained on the entire surface of sifter by means of aerodynamic air channel and air regulating valves. Bran and similar light materials are kept in suspension due to vacuum influence and transported to discharging channel and collecting box fitted below. The product (semolina) is separated from bran to be classified by means of sieves in accordance with granules.

FEATURES & ADVANTAGES OF PURIFIER

| 1. |

High capacity by using extended sifting surface. |

| 2. |

Effective cleaning by using brushes. |

| 3. |

Adjustable sifting speed. |

| 4. |

Minimum preventative maintenance and trouble - free operation by means of vibro - motor drive. |

| 5. |

Noiseless working condition. |

| 6. |

Easy cleaning process and hygienic working conditions. |

| 7. |

Light metallic sieve frames with adjustable tightening device. |

| 8. |

Quick and easy replacement of sieves. |

|