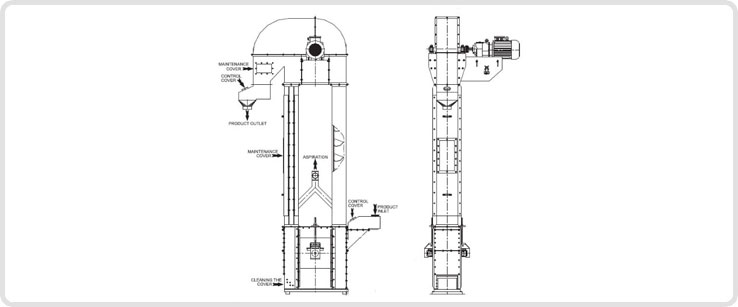

BUCKET ElLEVATOR

SCOPE OF BUCKET ELEVATOR

Belted bucket elevator is very ideal for vertical conveying of bulk materials or products, which have particle size up to 50 mm. For procedural reasons, the elevation of products, either in silo plants or in processing plants, is compulsory in almost all cases. For this purpose, buckets, which are fixed to a belt, convey the material from the inlet at the elevator foot to the elevator head, where the buckets are emptied when the belt is redirected. The Belt and Bucket elevator MGEL is designed for conveying up to 200 tons per hour. Floury as well as fine-grained and coarse-grained materials can be elevated up to a height of 60 meters.

APPLICATIONS OF BUCKET ELEVATOR

| It is designed to be used for both food and non-food industrial applications. |

| At food processing industry. |

|

| Flour, semolina and feed mills. |

| Food processing systems. |

| Coffee and cocoa processing plants. |

| At chemical and similar plants. |

| At cement factories. |

| At fertilizer plants. |

| At stone and lime plants. |

| At other similar industrial plants. |

|

STRUCTURE OF BUCKET ELEVATOR

The whole body is fabricated from steel sheet. Because of international safety regulations, inspection and installation covers should only be opened by suitable tools. The driven system is designed to move only in one direction. Reverse movementisn't permitted. For special applications, mostly worn surfaces are supported (covered) with replaceable plates.

| 1. |

With direct-coupled reducer motor. |

| 2. |

With chain or belt-pulley driven reducer system. |

|

FEATURES & ADVANTAGES OF BUCKET ELEVATOR

| 1. |

High efficiency with less power consumption. |

| 2. |

Easy and minimum maintenance. |

| 3. |

Durability and long lifetime. |

| 4. |

Smooth operation. |

| 5. |

Movement direction control switch for safety precaution. |

|